All threaded holes in the block and cylinder head should cleaned and tapped with a thread chaser. All bolts being installed should be lubed with a light oil or anti-seize on the bolt threads before assembly.

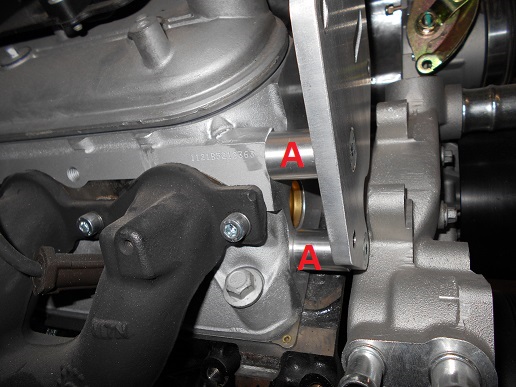

*We recommend leaving all of the bolts slightly loose until all the parts are installed. Then go back and torque each bolt to 28 ft. lbs. Install the smaller rear bracket using 2 "A" spacers between the bracket and passenger cylinder head using two counter sunk bolts as shown. Leave these bolts loose, do not tighten yet. On some VVT and corvette engines, the water pump must be removed to install the lower bolt.

Corvette accessories do not use an "A" spacer. The rear bracket bolts directly to the head.

Using the longest bolt and a stainless washer, install the larger front bracket using 1 "B" spacer between the two brackets and 1 "A" spacer between the rear bracket and the cylinder head.

Install the remaining two "B" spacers between the front and back bracket using the two countersunk bolts through the front plate and thread into the rear plate.

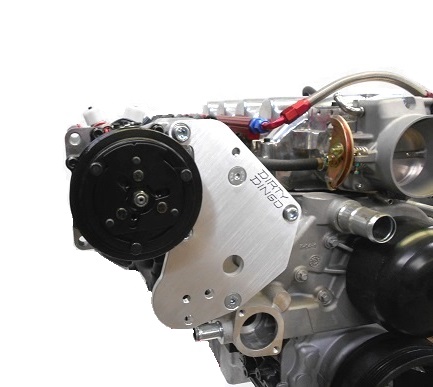

Now install the Sanden compressor between the two brackets. The compressor should be installed against the front bracket and spacers "C" between the backside of the rear bracket and the compressor. Use stainless washers on both sides.

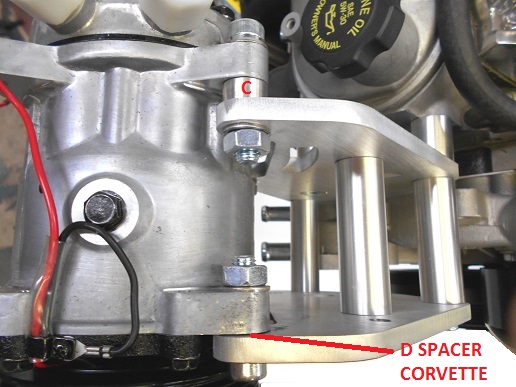

The Corvette assembly will use "D" spacers and have two additional "E" spacers.

These additional spacers are placed between the backside of the front bracket and in front of the compressor ears.

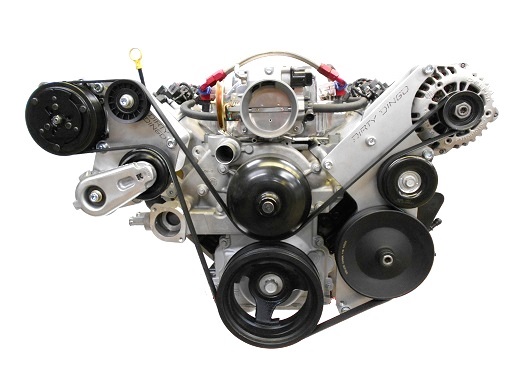

While lifting the weight of the compressor, tighten the counter sunk bolts first, rear bracket to cylinder head, then the front bracket, and finally the compressor to 28 ft. lbs. Next install the upper pulley with an aluminum spacer between the machined pulley stand and the front bracket. The additional stainless washer and nut go on the backside of the pulley bolt to secure this bolt from coming loose.

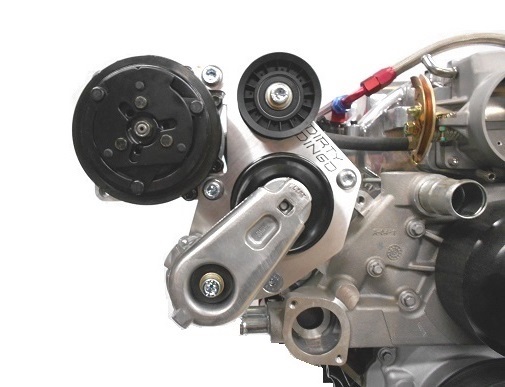

TENSIONER INSTALLATION-

Place the flat aluminum spacer plate that comes with the tensioner between the tensioner and the front plate as shown. Tighten tensioner bolt to 28 ft. lbs.

To install the belt place a 3/8 ratchet and extension into the front of the tensioner and twist down.

BELT SIZES-

Stock truck accessories-

Small case alternator Gates K061115

Large case alternator Gates K061123

Truck accessories using Dirty Dingo billet Alt/PS high mount bracket-

Small case alternator Gates K060990

Large case alternator Gates K060997

Truck accessories using Dirty Dingo billet Alt/PS low mount bracket-

Small case alternator Gates K060960

Large case alternator Gates K060975

Truck accessories using Dirty Dingo idler relocation bracket-

Small case alternator Gates K061177

Large case alternator Gates K061187

Truck accessories using Dirty Dingo idler relocation bracket non/power steering

Small case alternator Gates K060895

Large case alternator Gates K060905

Factory Corvette or Dirty Dingo Corvette style LS1 Alt/Ps bracket-

Small case alternator Gates K061000

Large case alternator Gates K061010

Stock 1998-02 Camaro accessories-

Gates K060988

Stock 2010-2015 Camaro accessories-

Gates K061031

Dirty Dingo Corvette Style and Stock Corvette accessories-

Small case alternator Gates K061000

Large case alternator Gates K061010

* When using large case Truck alternator add 3/4" to belt length.

* When using small diameter power steering pulley subtract 2" from belt length.

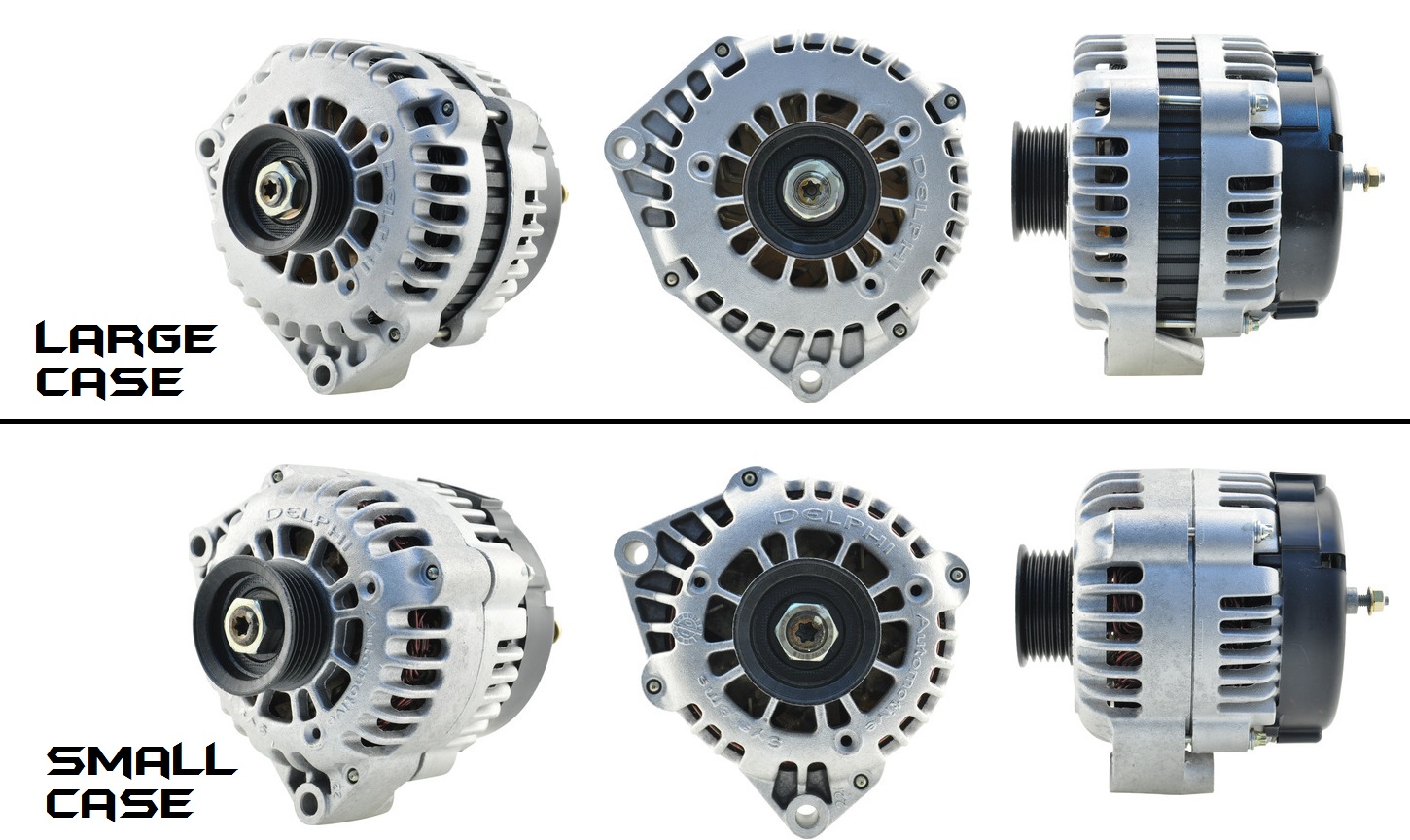

Small case alternators are 135 amp and lower. Large Case alternators are 140 amp and higher.

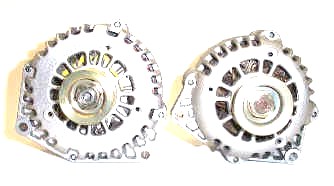

Large case is on the left-