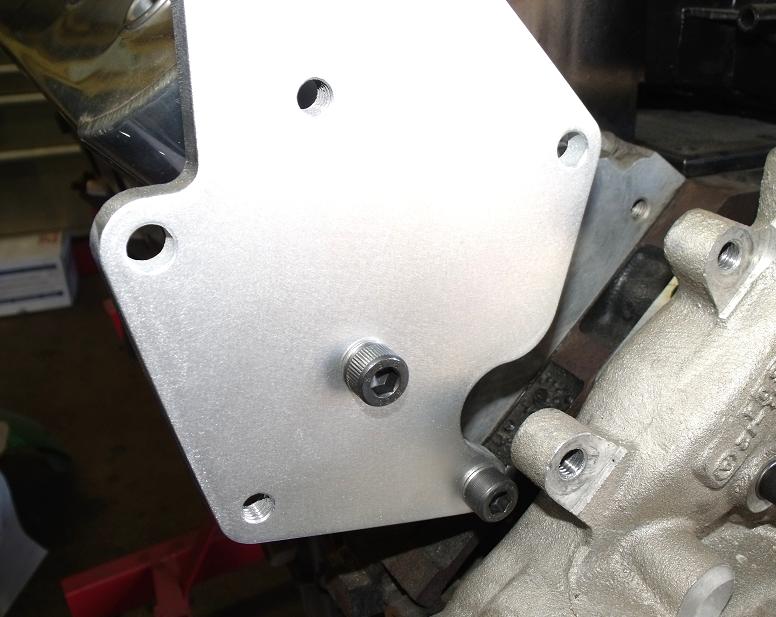

All threaded holes in the block and cylinder head should cleaned and tapped with a thread chaser. All bolts being installed should be lubed with a light oil or anti-seize on the bolt threads before assembly.

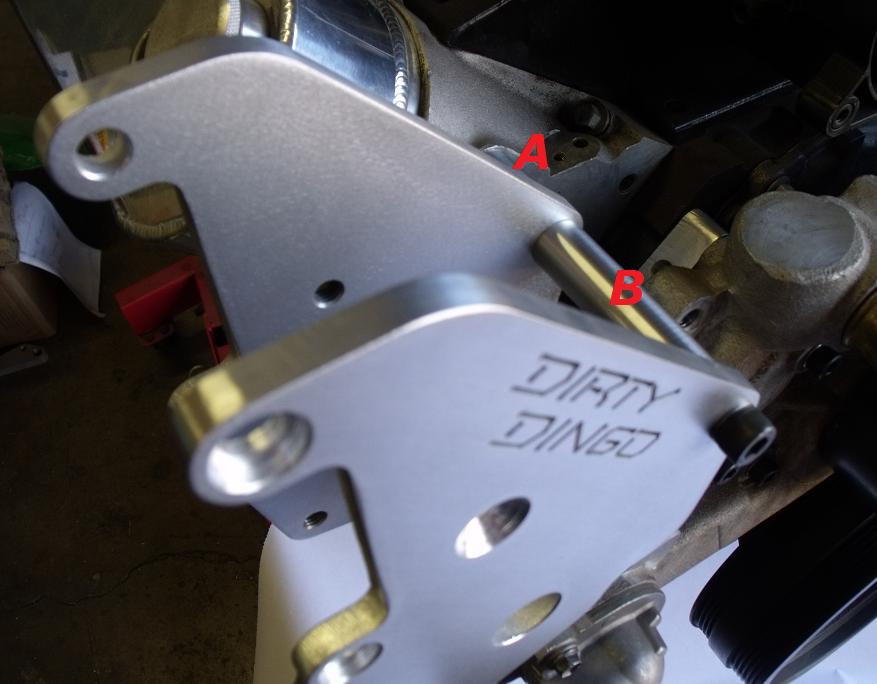

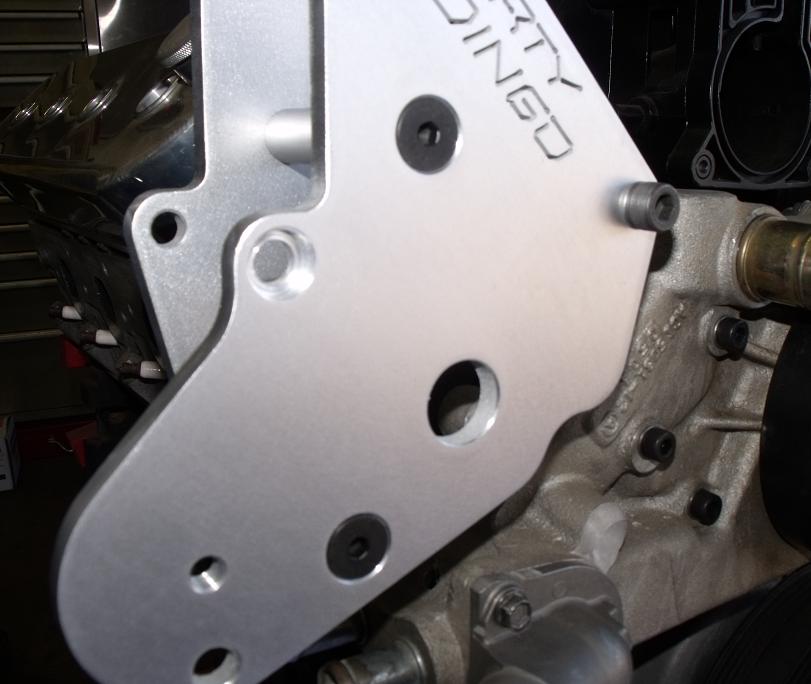

*We recommend leaving all of the bolts slightly loose until all the parts are installed. Then go back and torque each bolt to 28 ft. lbs. Install the smaller rear bracket using 2 "A" spacers between the bracket and passenger cylinder head using two bolts and stainless washers as shown.

Using the longest bolt and a stainless washer, install the larger front bracket using 1 "B" spacer between the two brackets and 1 "A" spacer between the rear bracket and the cylinder head.

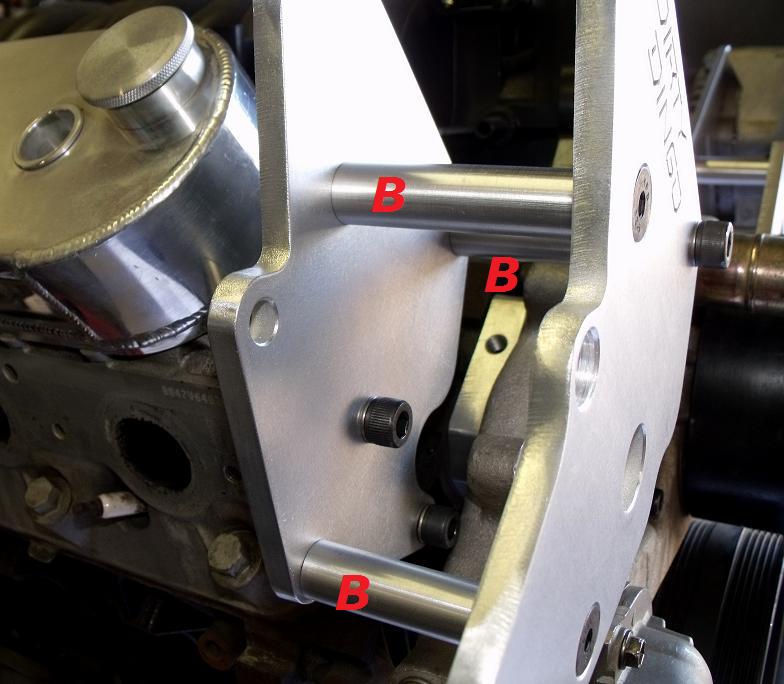

While placing the remaining "B" spacers between the front and back bracket, install the two countersunk bolts through the front plate and thread into the rear plate.

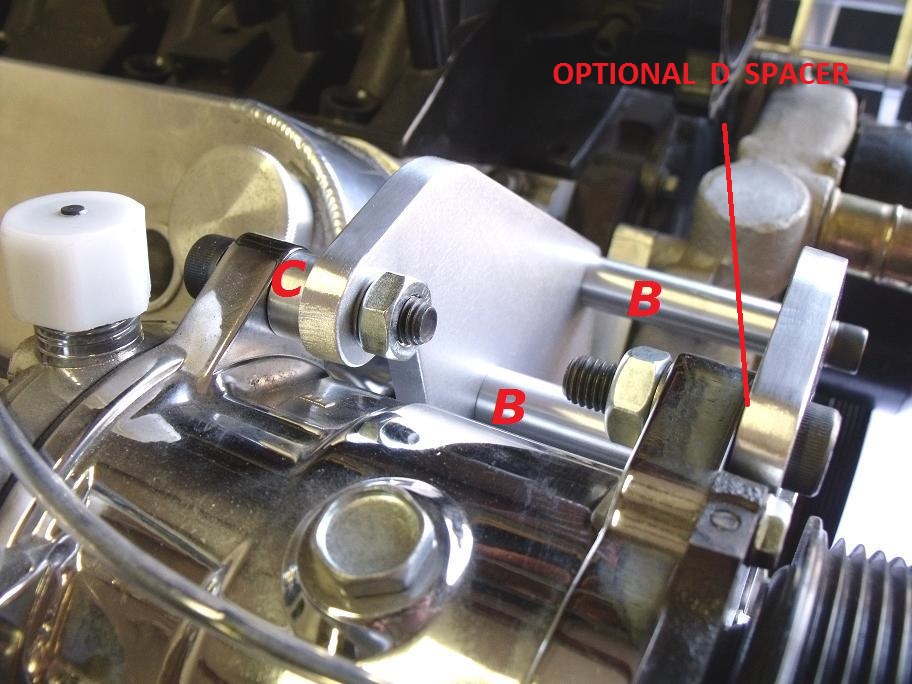

Now install the Sanden compressor between the two brackets. The compressor should be installed against the front bracket and spacers"C" between the backside of the rear bracket and the compressor. Use stainless washers on both sides. The Corvette assembly will have two additional "D" spacers. These are placed between the backside of the front bracket and in front of the compressor ears.

While lifting the weight of the compressor, tighten all bolts to 28 ft lbs. Start with the rear bracket first, then the front bracket countersunk bolts first, and finally the compressor.

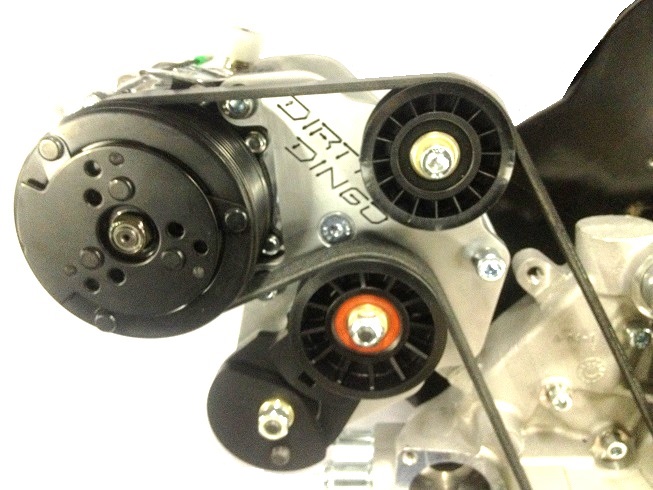

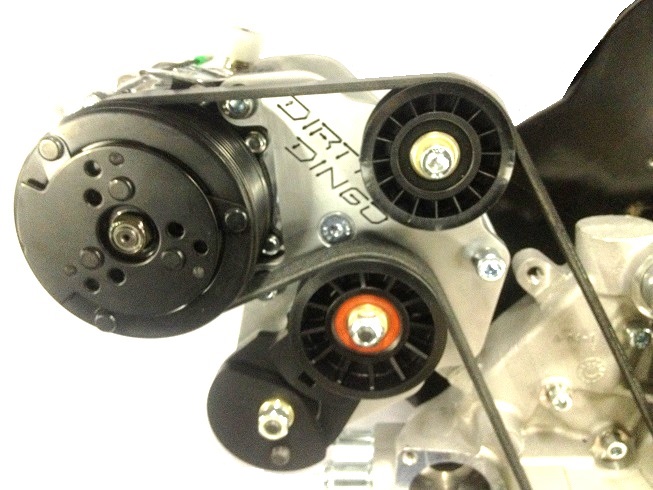

TENSIONER INSTALLATION-

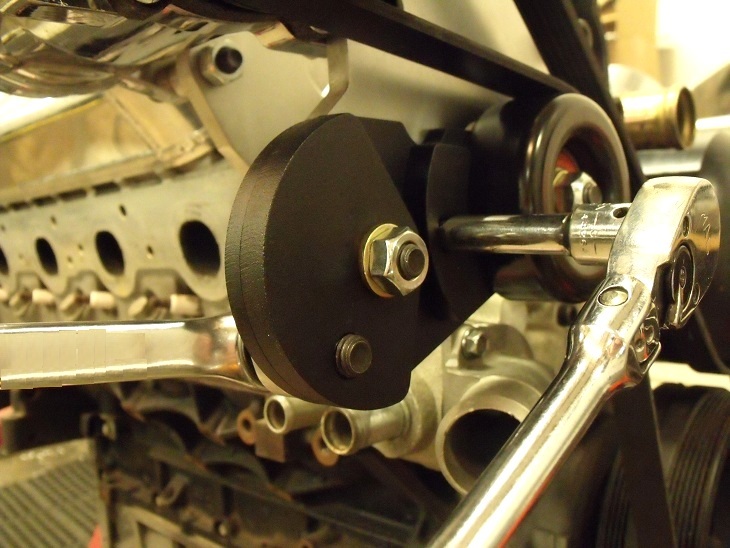

The tensioner comes assembled. Install the 40 MM bolt with stainless washer into the bottom of the a/c bracket from the backside so the bolt protrudes out the front.

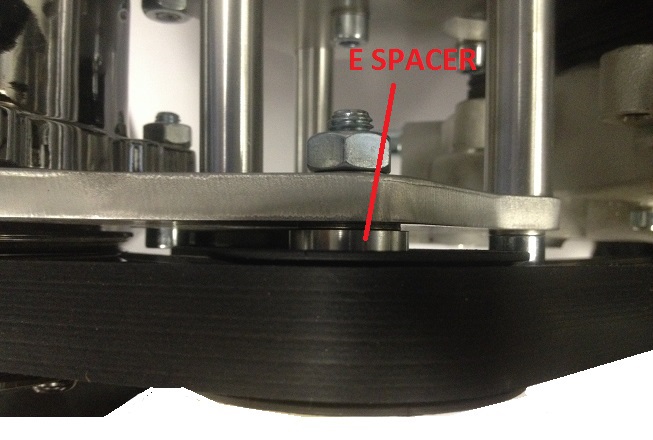

Place the aluminum shim onto the bolt as shown.

Place the tensioner onto the bolt keeping the large hole lined up with the aluminum shim.

Install the 12 MM bolt, washer, and lock washer from the backside through the plate, through the aluminum shim, and into the steel cover plate. The belt should be very tight when installing. Wrap belt around all accessories and slip over the water pump last. If the belt is too loose you will not be able to set the correct tension.

Place a 3/8 ratchet and extension into the front of the tensioner and while pushing down to tension the belt- tighten the 12 MM bolt on the backside to 40 Ft. Lbs. Proper tension can be set using a torque wrench at 25 ft. lbs. Then tighten the center pivot nut on the front to 28 Ft. Lbs. Place the belt on the inner most grooves towards the compressor bracket. The extra grooves on the clutch will be exposed to the front of the compressor. The belt should be very tight when installing. Wrap belt around all accessories and slip over the water pump last. If the belt is too loose you will not be able to set the correct tension on the belt. This is a starting point for figuring out the correct size belt for your application. Direct fit spring loaded tensioner Gates 38164.

Spring Loaded Tensioner-

Gates 38164

Belt sizes-

Stock truck accessories-

Gates K061120

Truck accessories using Dirty Dingo billet Alt/PS high mount bracket-

Gates K060997

Truck accessories using Dirty Dingo billet Alt/PS low mount bracket-

Gates K060975

Truck accessories using Dirty Dingo idler relocation bracket-

Gates K061177

Truck accessories using Dirty Dingo idler relocation bracket non/power steering

Gates K060895

Camaro accessories-

Gates K060984

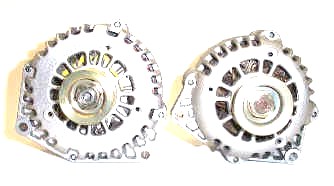

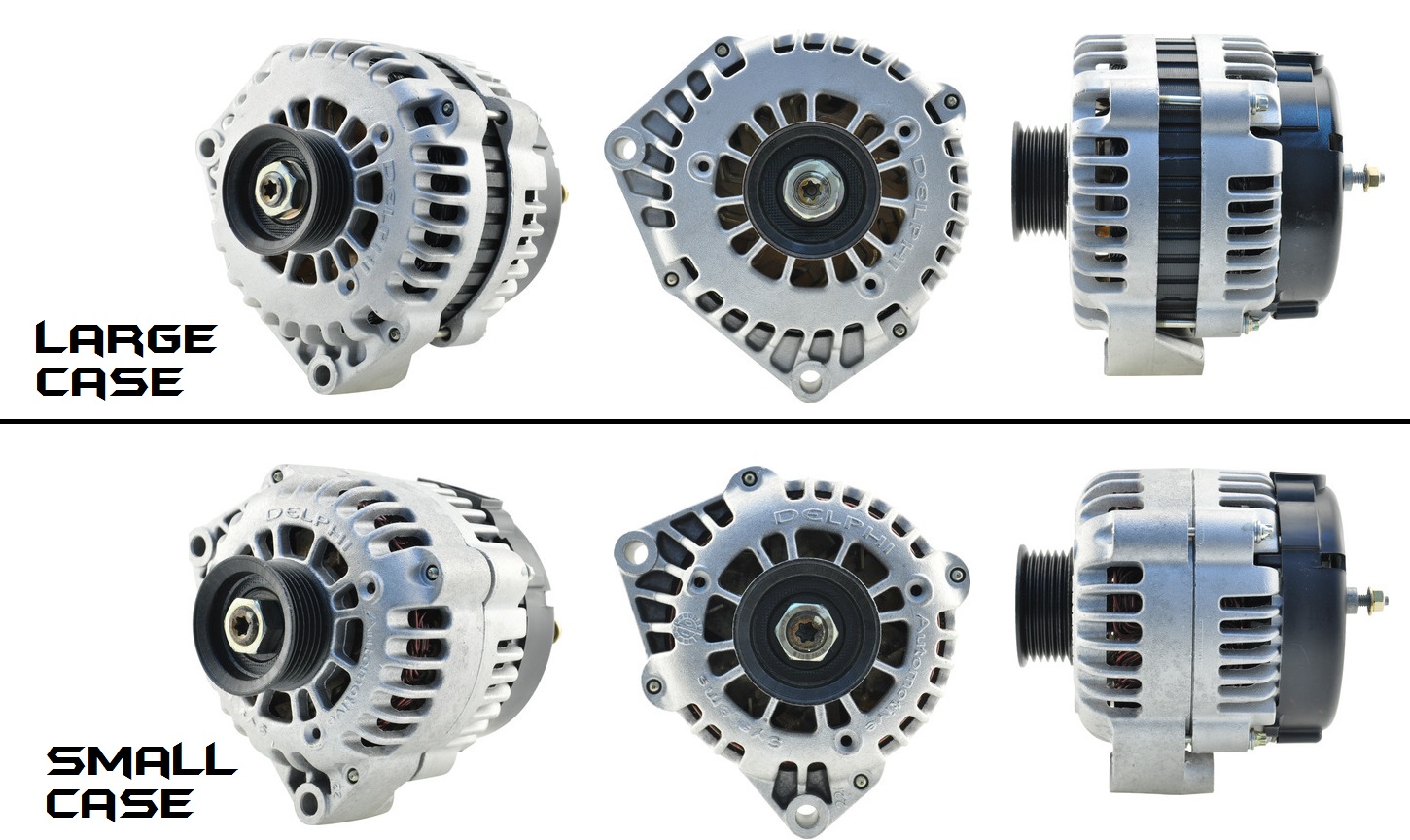

* When using large case alternator add 3/4" to belt length.

* When using small diameter power steering pulley subtract 2" from belt length.

Small case alternators are 135 amp and lower. Large Case alternators are 140 amp and higher.

Large case is on the left-